Pros and Cons of Polyethylene Armor

Share

Polyethylene (PE) body armor is an excellent option if you want rifle-rated protection while keeping the weight down. If you’re more focused on pistol-rated armor, you should check out our soft armor. If additional weight is not a concern then you may want to check out our steel alloy.

As with all types of body armor, polyethylene armor has both its highlights and drawbacks. In this section, we hope to give you an overview of PE armor plates so you can determine whether they’re right for you.

Let’s dive into what polyethylene armor is in the first place.

What is Polyethylene Armor?

Polyethylene is a lightweight and versatile plastic that’s been a popular option for use in body armor. As you read about polyethylene, you might see the term UHMWPE. UHMWPE stands for Ultra High Molecular Weight Polyethylene. We’ll often refer to it as PE armor for short. PE body armor “captures” the bullet in its material. Contrast that with soft armor, which “catches” the bullet, or steel armor, which disintegrates it.

When a bullet meets polyethylene, the heat causes partial melting of the material. That allows the bullet into the plate just enough for the remaining un-melted portion to stop it. The polyethylene rehardens after slowing the bullet down, resulting in a captured threat.

Is Polyethylene Stronger Than Kevlar?

Yes. Kevlar is a woven material while UHMWPE is pressed and layered. PE has similar properties to Kevlar just with the added function of polymer reinforcement.

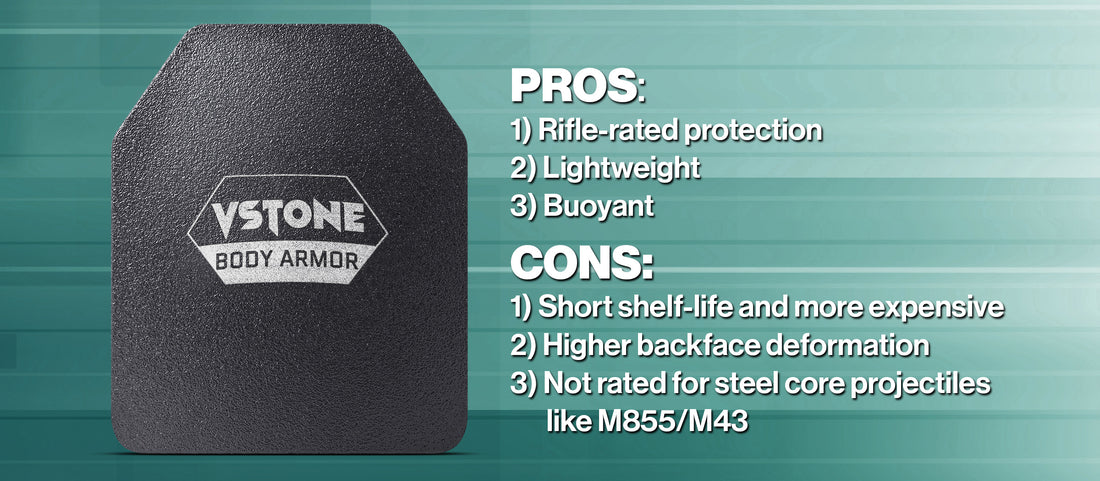

Pros of Polyethylene Body Armor

You’ll find polyethylene products in our P series of body armor strike face inserts. Having laid the groundwork, we’ll now go over some of the benefits of polyethylene armor.

-

Rifle-Rated Protection: A polyethylene armor plate is the only way to get rifle-rated protection from lightweight body armor. The protection you get from polyethylene is comparable to steel and can stop all of the following:

- 7.62x51 M80 Ball at 2,780 feet per second (FPS)

- 5.56x45 M193 at 3,150 FPS

- 7.62x39 AK-47 at 2,380 FPS

- Durable: Unlike the brittle composition of ceramic armor, polyethylene can withstand a fall to the ground. Though the ceramic may survive, you wouldn’t know for sure without an X-ray. Users of PE body armor appreciate the peace of mind they have, knowing there aren’t any hairline cracks that could compromise the integrity of the plate.

- Lightweight: If you need rifle-rated protection from a plate that’s less than 4 pounds, PE is for you. The lightweight design allows you to engage in physically strenuous activities. Heavier plates tend to cause quicker fatigue. That's the primary benefit you'll get from PE armor plates.

- Buoyant: The fact that PE plates are also neutrally buoyant is an attractive feature. It’s a particular benefit to anyone working around water. In those situations, steel is probably not the best option. Going into the water with 18 pounds of steel hanging from you is a dangerous scenario. With PE, it’s nice to know you can wear your armor without it endangering your life if you end up in the water.

- Multi-Hit Capable: Because of the unique way polyethylene armor “captures” the bullet, it is multi-hit capable. That means there should be no loss in the effectiveness of the plate when hit. Of course, that doesn’t mean you can take endless hits without issue.

Cons of Polyethylene Body Armor

As with all body armor categories, PE has its limitations. Let's look at some of those negatives, so you can determine whether this is your best option.

- No Edge-to-Edge Protection: Per the National Institute of Justice (NIJ) standards, the outer edge of your PE armor may not be a ballistically-rated zone. That could be anywhere from 2 to 3 inches from the edge. Consider that if you purchase a 10"x 12" PE plate, you can't necessarily count on 120 square inches of ballistic protection. If that's a concern, you could move to steel armor to get complete edge-to-edge protection. For more on that, read more about armor performance.

- Thicker and Less Concealable: Since polyethylene is so light, it takes quite a bit of material to accomplish its purpose. You're looking at about a 1" or more of thickness, making this armor very tough to conceal. PE tends to be the thickest material of all body armor choices. If you’ve ever worn concealed body armor before, you know how much of a difference that thickness makes.

- Higher Backface Deformation: When the projectile strikes the armor, the plate deforms to the interior side, against the body. That is what we call backface deformation (BFD). Remember, PE doesn’t disintegrate and deflect the bullet, but rather it captures it. So, despite PE armor’s thickness, a polyethylene armor plate test will reveal substantial levels of BFD. BFD must be less than 44mm per the NIJ .06 standards, and there shouldn’t be any issue passing that test. But even a passing grade is enough to leave your internal organs bruised and damaged. Therefore, we recommend wearing a trauma pad in conjunction with any armor insert.

- Short Shelf-Life and More Expensive: So how long does polyethylene armor last? The polyethylene armor shelf life is 5 years, standard for most armor. But what does that mean? Does it just stop working when it turns 5 years old? No, the armor may become less effective before or after the 5-year mark. If you’re looking for something that will last you longer, you may want to give steel armor a look. With its 20-year shelf life, you won't have to worry about replacing it as often. Replacing armor every 5 years can be unattainably expensive for the average citizen.

- Sensitive to Extreme Temperatures: Polyethylene is sensitive to extreme temperatures. Leaving your PE plates in excessive heat or freezing weather can degrade the material. And it's easy to do, as some people may store their armor in the trunk of their car for extended periods. That can make the plates less effective, and you may not even know it until it’s too late.