The Science Behind Our Advanced Ballistic Plate Design

Share

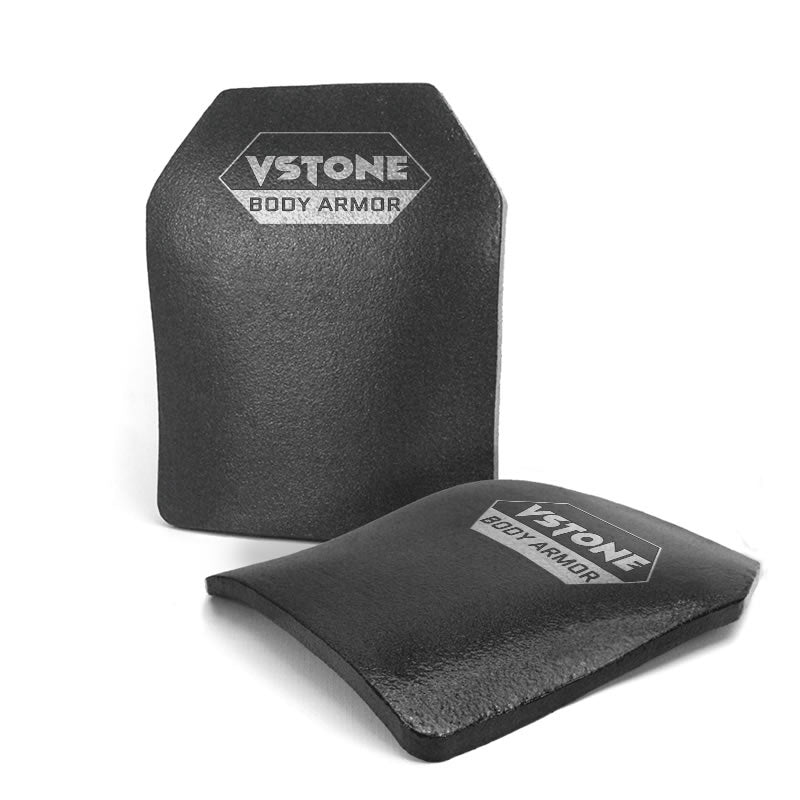

Bullets are scary, and feel free to look this up because it is important that we protect ourselves from them. Special Vstone Armor plates that can be added to a vest and stop bullets from the gun. The plates are constructed from highly durable materials, tough enough to withstand a bullet and fast moving bullets which make sure that we remain safe in danger circumstances.

The Way We Manufacture Our Bulletproof Plates

Manufacturing a great bullet-stopping armor plate is quite hard really. It requires meticulous planning and a lot of hard work. The first criteria is what materials we can find capable of taking the most punishment, which is necessary for making sure they are able to fulfill their job properly. So in this case, we have chosen the top material and now it's time to cut and give shape/size what our Ceramic bulletproof plates need to be…

When the materials are formed to our liking, we stack them together and put into special machines. This makes the plates even stronger than they were before. That made Jordan heavier in the same way that pressing down on dough to make it thicker and tougher. In the end, we layer them a protectant to make our plates super durable. This layer is designed to protect the javelin plates from unnatural destruction and wearing time.

The Physics of Heavy Armor

What makes our ceramic ballistic plates so efficient? The key lies in the unique materials we use. Last but not least, these materials are also very good in terms of strength and toughness: they resist remarkably well on external forces which try to disintegrate them. Ceramic and steel, for example, are heavier due to the bulk needed so protect a plate from bullets; while Kevlar is far lighter but much less resistant.

This makes ceramic a good bullet stopper. It is very hard and has excellent stiffness properties, making it an ideal choice for the purpose of stopping bullets. In case of the bullet hitting a ceramic plate, this may shatter it upon impact preventing then penetration and therefore damage. Steel is another material that we use and it too has a high tensile strength which means it can hold up to force better. Steel is strong, so it gets used in armored vehicles such as tanks. The last but not least, Kevlar which is a material used in bulletproof vests. This makes Kevlar a decent lightweight, and flexible choice perfect for wearing as armor.

The Basics of Ballistic Protection

In order to generate a plate capable of stopping bullets, we have make physics also work against it. A bullet hitting a plate produces tremendous force. It is a very strong force that should be distributed in some way over the entire plate so that it will not fracture.

We have to achieve this almost impossible tandem by means of hard and soft materials. These are the ceramic and steel hard materials used to actually halt a bullet. Meanwhile, the softer substrates mimic a kind of pillow (see: Kevlar). They absorb some of the energy from a bullet and spread it across as much of the plate as possible. Goliath's unique blend of alloys are quite necessary when you consider what a single bullet strike could do to an unprotected piece of plate.

Why Sizing and Fit Matter?

One of the core components in developing a ballistic plate is ensuring that it fits properly. If this plate is not large enough, it will offer less protection — and can put you at risk. On the other hand, if you have too much armor on your body and a plate that's too big it can cause discomfort meaning you may not be able to do what is required of you.

Before we ever begin the manufacturing, as a step of quality control and precision, our plates are carefully measured to make sure they fit perfectly. It is this attention to detail that ensures our plates offer the best protection while remaining wearable. This is crucial to avoid the stress over bad, unfit gear and focus more on their work at hand.

Making Our Plates Even Better

It is our mission at the company to continuously improve on these ceramic bulletproof plate and make them even better than what they are now. Myrcke Engineering is continuously looking for advanced materials and innovative method improving anodic plates.

We are looking at building much lighter and flexible plates. It would allow people to wear them and be mobile, yet still afford the utmost protection. In addition, we are also exploring how to make our plates heat and environment resistant so that it can deliver solid performance in all scenarios.

And we are proud of it that our ballistics plates is among the best worldwide. We strive to keep innovating in how we design and build our technology so it lets people feel safe, secure—and unconstrained by threats.