Your 10x12 is Really an 8x10 (If It's Not Steel)

Share

“In 2005 and 2006, two law enforcement officer-involved shootings resulted in injuries to the officers when bullets were not stopped in the officers’ body armor….

The National Institute of Standards and Technology (NIST) investigated...to provide guidance to NIJ. The research effort concluded that in both cases the bullets struck the body armor too close to an edge for the armor to be able to reliably stop the bullet...the armors appeared to provide sufficient protection when struck by bullets away from the edge, in the region normally tested during compliance testing.”

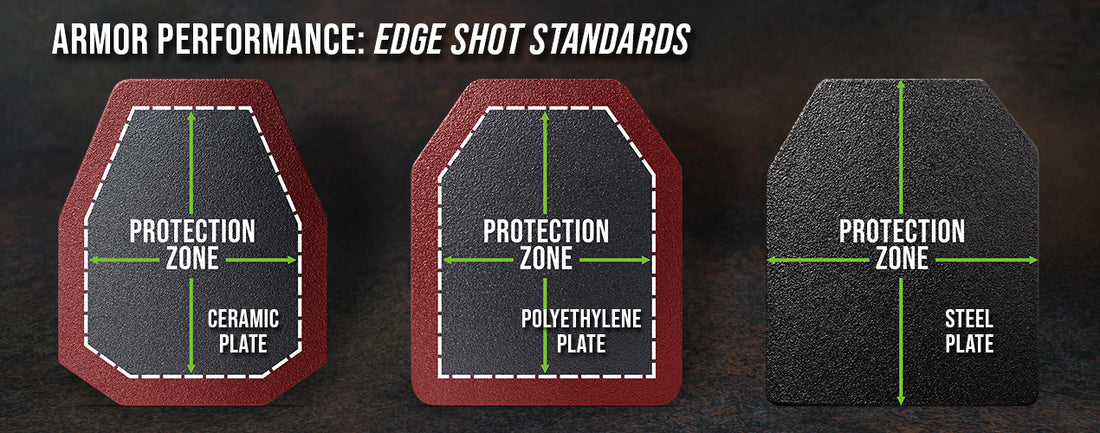

These NIST study excerpts shed light on an important issue: Many plates are not able to protect the wearer if they are shot on the edge. And what’s more, NIJ Certification explicitly allows for this leeway.

This article will dive deeper into that concept, both to explore the NIJ’s standards and to examine steel armor’s unique ability to supply edge-to-edge protection.

The NIJ Standard

To start, the NIJ Standard for testing body armor doesn’t require companies to test edge protection: It forbids it.

According to the NIJ 0101.06 guidelines, “The minimum shot-to-edge distance for many test threats is now 51 mm (2.0 in), as opposed to 76 mm (3.0 in) in NIJ Standard–0101.03 and NIJ Standard–0101.04….

For the heavier threat rounds used against the Type IIA, II, and IIIA armors, the minimum shot-to-edge distance remains at 76 mm (3.0 in).”

A test shot against a plate of armor is not valid unless that shot is an inch away from any edge of the plate. To clarify, some read the NIJ standard to mean that a shot has to be two inches away from any edge; it actually means it has to be one inch away from either edge, making for two inches of shot-to-edge distance.

With that said, were a test shot to land closer than one inch away from the edge, that shot would be invalid and its results not counted - no matter if that result was a plate failure. In effect, the performance of a 10x12 is really judged as if it were an 8x10 (an inch smaller on each side).

At first glance, this is a strange rule: Armor is intended to protect the wearer, so why would the NIJ’s standards allow for an exception? The answer is fairly simple:

Most materials cannot supply edge-to-edge protection.

Polyethylene and Ceramic plates, at least in their modern construction, are inherently weaker on the edges. Because of this, the NIJ has essentially determined it unreasonable to expect PE and Ceramic plates to perform on the edges when no existing plates of those materials do so. For this reason, some suppliers of these plates will simply put foam around the outer edges of their plates in place of armor, since for the NIJ’s purposes the performance of foam is equally acceptable.

There is one exception to this rule, however: Steel plates are quite capable of edge-to-edge protection. This is partly because Steel is monolithic: It is made of one material that is shaped and coated, rather than multiple materials that are molded together. Ceramic is different in that it actually consists of ceramic in front of some other material attached to the back to catch the bullet (fiberglass, for instance). Polyethylene is also not monolithic. With that said, only a Steel 10x12 is truly going to guarantee protection for all the areas it covers.

Here are two main takeaways from these facts:

- Consider how important edge performance is to you. Edge-to-edge protection isn’t a given with all materials. If you find the difference between a 10x12 and an 8x10’s protection significant, note that and choose your ideal armor material accordingly. Only a Steel 10x12 is truly going to be protection for that entire area.

- NIJ Certification is not an all-encompassing test. The NIJ’s standards for body armor performance cover quite a few things, but there are notable exceptions. Edge-to-edge performance is not on the list of requirements to get that certification. Of course, this is because a ceramic or polyethylene plate would never be able to meet that requirement by virtue of its material, so this is in no way to fault the NIJ. It is simply an important fact to keep in mind when comparing plates.